COLD BENDING

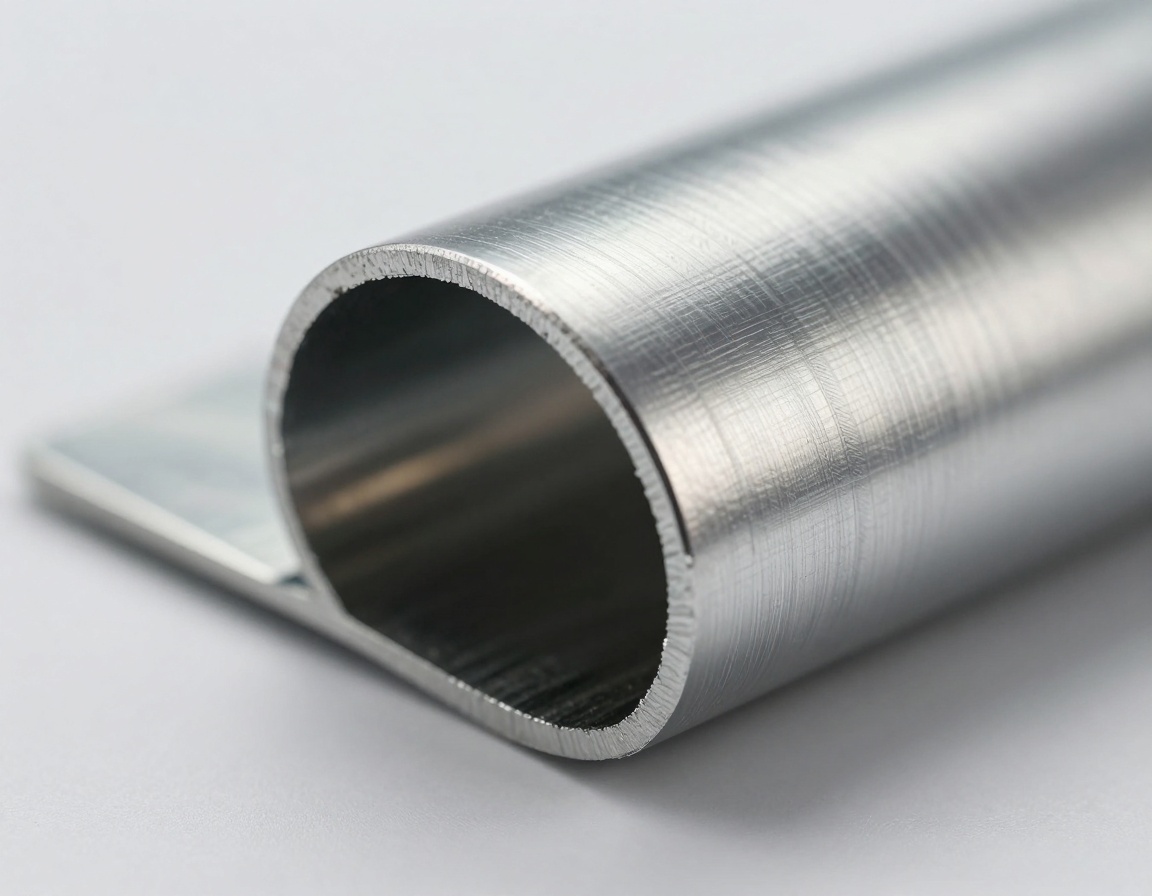

Precision CNC press brake bending for stainless steel, EG steel, and aluminum. Ideal for channel letters, box-up signage, architectural panels, and custom metal structures. Fast turnaround and competitive pricing in Klang Valley.

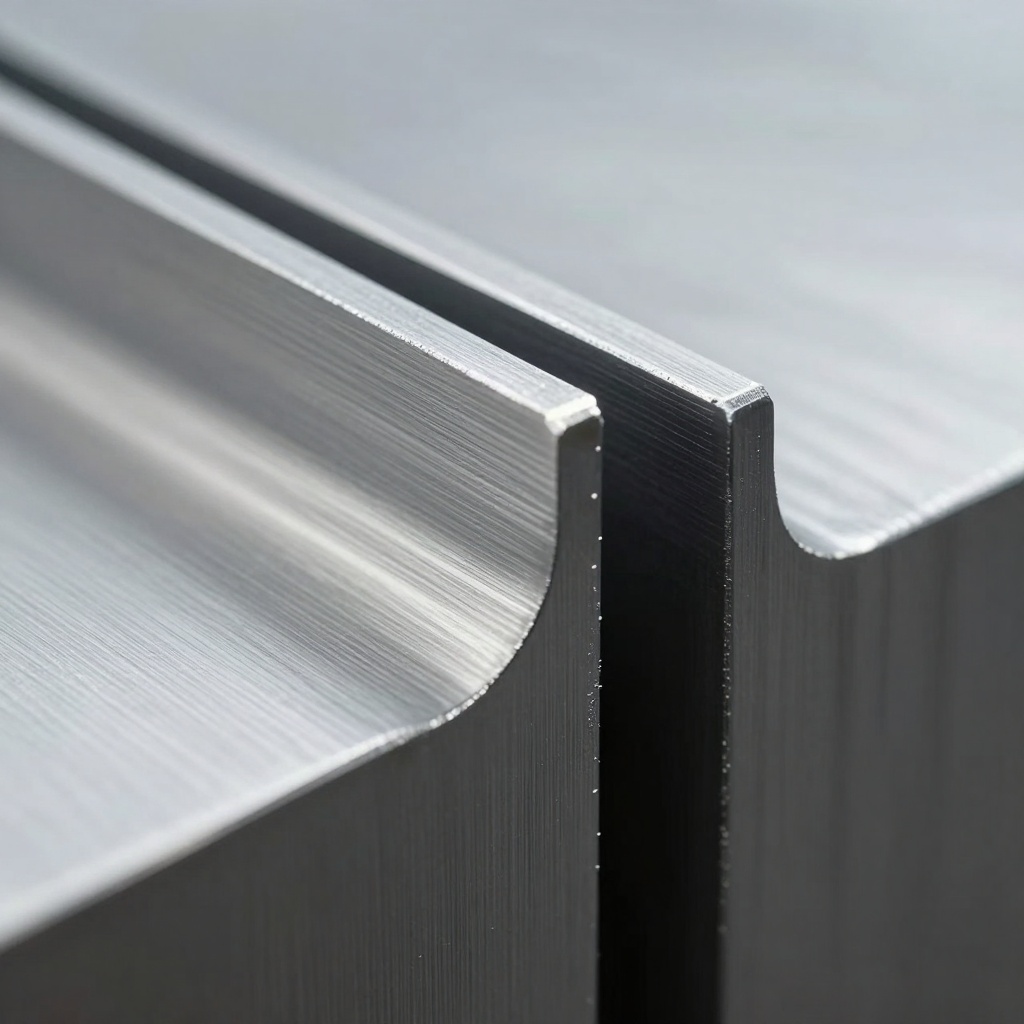

- High precision angles (±0.5° tolerance) ✓

- Clean, sharp bends with minimal distortion ✓

- Maintains material strength and properties ✓

- Suitable for multiple bend sequences ✓

- Fast turnaround time (3-5 days) ✓

Get an Instant Quote

What size is your project?

Price Estimate

How much does metal bending cost in Kuala Lumpur?

Metal bending prices start from RM 20 per piece for simple bends. Final cost depends on material type, thickness, number of bends, and quantity. Complex multiple-bend parts cost more due to setup time.

What's the difference between cold bending and hot bending?

Cold bending uses mechanical force at room temperature, maintaining material properties. Hot bending uses heat and is used for acrylic or complex curved forms. Cold bending is faster and more cost-effective for sheet metal.

How many bends can you do on one piece?

We can perform multiple sequential bends as needed for your design. The limit depends on the part geometry and accessibility for the press brake tooling. Complex channel letter designs often require 4-6 bends per piece.

+ 5 more questions answered on request